Known worn out hydraulic circuits addressed: Solenoid regulator pressure, Torque converter apply and release, Shift solenoid performance codes or false PO751 due to sticking or dragging clutch select valves. In addition to conventional wear correction, the new and improved six-speed General Motors valve bodies are upgraded to address this unit’s most problematic torque converter clutch issues. The TCC is one of the very first things to fail due to low apply pressure when hot. Valve Body Pro has fortified the weak points of the TCC function with proprietary upgrades allowing an increase in TCC apply during deceleration and city driving, dramatically increasing life expectancy of the torque converter clutch and preventing costly hard parts damage. Allows TCC apply pressure increase during deceleration and under city driving. Significantly increases the life of TCC. All valve bodies are run through a series of shift cycles at operating temperature, then precisely calibrated using state-of-the-art valve body test equipment to verify proper operation of the pressure/control circuits. Computer-generated test results are compared side-by-side with new OEM valve bodies. This comprehensive integrated testing process is only possible using proprietary software in conjunction with the latest generation Hydra-Test® valve body machine.

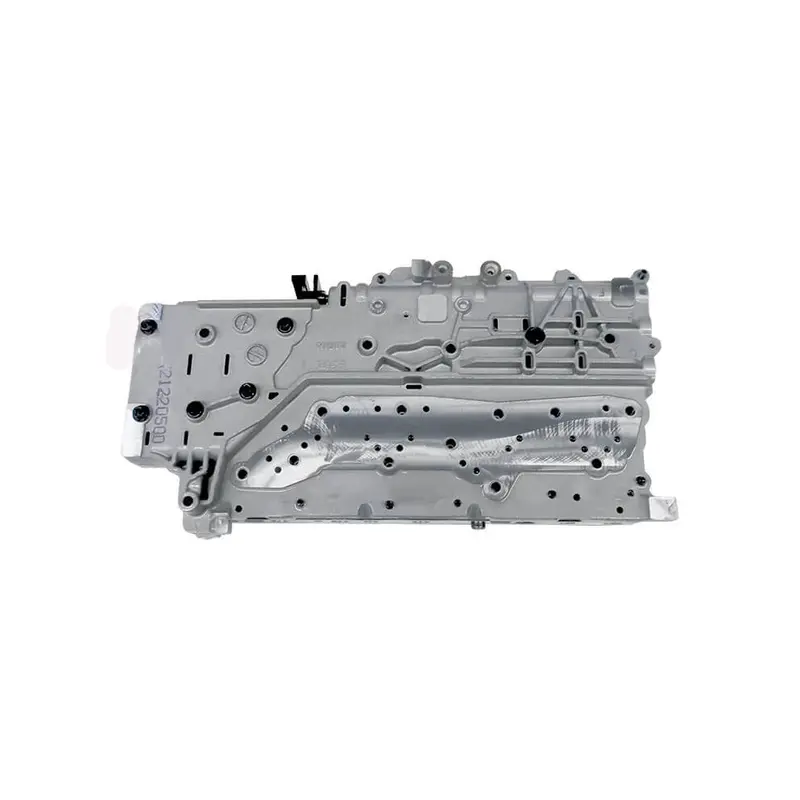

Main Valve Body Assembly; Casting ID "C" ; TEHCM Not Included